Constant Voltage vs. Constant Current LED Driver

A Frequently Asked Question:

"Do I need to use a constant voltage or a constant current driver to drive my LED strips?"

As a pioneer in providing reliable and high quality LED drivers, Amperor has been asked questions like this many times. Unfortunately, there is no simple answer to this question. There are different approaches to consider depending on the stage of the design cycle of the LED application and the structure of the LED strips in use. This article will explain the selection criteria - starting with the basic characteristics of the LED itself.

Constant Current source is the preferred method of driving one LED.

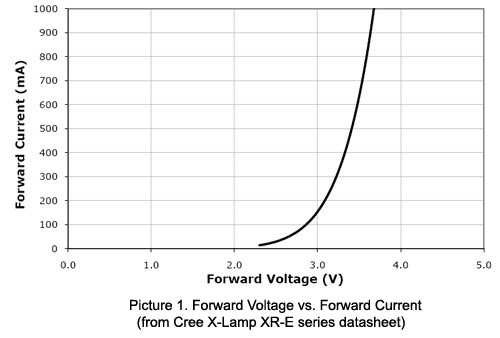

When a light-emitting diode is turned on, it releases energy in the form of photons. Because of the lower power consumption, the longer lifetime and the smaller foot-print, LED has been widely adopted in the signage and lighting industries. One unique behavior of the LED is the exponential relationship between the applied forward biased voltage and the resulting current flowing through its body. Please see "Picture 1" for an example I/V curve from Cree. After the LED is switched on, a small 5% deviation on the voltage source (from 3.3V to 3.5V) can create a 100% difference (from 350mA to 700mA) in forward current on the Cree Lamp XR-E LED.

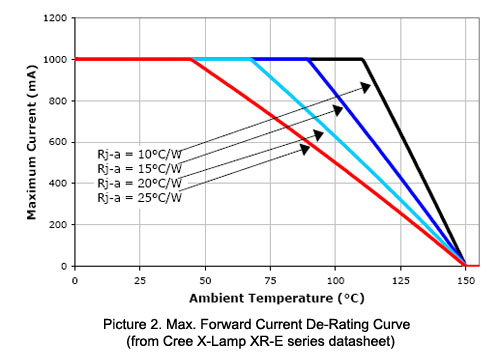

Although a higher forward current can force the LED to emit brighter light, it also tends to over-drive the LED. Please see the "Picture 2" for an example on how Cree specifies the maximum forward current and its de-rating curves in different ambient temperature conditions. The 5% voltage deviation example used in the previous paragraph can push the forward current well pass the limit in a higher temperature environment. The excessive forward current will result in extra heat generation and a significant reduction in LED lifespan. Therefore, a constant current source is the preferred method to drive one LED.

Semi-assembled LED strips are available to make the end application construction easier.

Lighting and signage engineers seldom rely on a single LED to produce the expected outcome. In a real world application, a group of LEDs are usually connected in both serial and parallel arrangements to create the desired light intensity, color and shape. It is neither convenient nor economical to build everything by hand from the single LED component level. Manufacturers have introduced various products to enable engineers to connect LEDs to a semi-assembled level in order to reduce the effort and the time in building up the end application. These products include, but are not limited to LED strips, LED strings, LED modules, LED bars and LED arrays.

The most basic LED strip design consists of a group of LEDs in serial connection with a current-limiting resistor above them. Please see "Picture 3" for an example of this configuration. If the value on the resistor position is carefully selected, then the LEDs on the same strip will be less prone to the variation of the voltage source. This enables the implementation of the more commonly used constant voltage drive to power the LED applications. The most basic LED strip design consists of a group of LEDs in serial connection with a current-limiting resistor above them. Please see "Picture 3" for an example of this configuration. If the value on the resistor position is carefully selected, then the LEDs on the same strip will be less prone to the variation of the voltage source. This enables the implementation of the more commonly used constant voltage drive to power the LED applications.

Numerous improvements to the LED strip design have been introduced through the years. Some vendors use the on-board constant current regulator to replace the current-limiting resistor while some employ advanced feedback monitoring circuitry to enhance the efficiency. Others add current balancing and smart protections onto the strip. With the constant current drive becoming more popular, some vendors even offer LED strips designed to use constant current drive only.

How do those LED strip designs affect the driver selection - constant voltage or constant current topology?

Whether the LED application is for the lighting or signage industry, there are always optical choices - such as intensity, color, shape and brightness Ė to be made when choosing LED strips. There are also other variables to be considered, including environmental factors (operational temperature, indoor / outdoor usage and the heat dissipation path) and budget restrictions. Although it would benefit us to convince the world that the LED driver is the most important component of any LED system, the optical, environmental and budget concerns must be addressed first. An LED system engineer should research and combine the appropriate LED strip designs to generate the wanted result. Once the design is finalized, the choice of which LED driver to use will become clear.

In other words, the first choice to be made is which LED strip to use. When itís time to select a driver, you may use the type: constant voltage or constant current, specified in the LED strip application note or use a 3rd party's driver, such as Amperor's LED power supply, in the same type specified in the application note, to achieve a better performance. The question of using a constant voltage or a constant current driver is usually one of the last to be answered.

Below is a list of the major benefits of using the constant voltage and the constant current topologies. Switch to a different LED strip solution if you want to use the different topology to enjoy the benefits of it.

- Advantages of using the constant current topology:

- Avoids violating the absolute Max. forward current specified for the LEDs and compromising the reliability

- Achieves more consistent brightness between different LED strips

- Advantages of using the constant voltage topology:

- A more familiar technology for the design engineers and installation technicians

- The cost can sometimes be lower

Amperor's constant voltage and constant current LED driver family

While there are always exceptions to every rule, we have determined that the sign industry employs more constant voltage drivers and the lighting industry utilizes more constant current drivers. If you are in the sign industry, you should consider using Amperor's LED modules, Amperor's UL879 certified Class II LED constant voltage drivers (ANP90, ANP155 or ANP240) and Amperor's dimming module (DIM-240) as your total design solution. If you are in the lighting business, you should consider using the Amperorís UL8750 approved constant current driver (ANP60, ANP106, ANP107, ANP206, ANP207, ANP100, ANP151, ANP105) to power your LED strips. Amperor is also capable of producing customized designs to meet all your unique needs. Please contact us by phone (281-807-3320) or by EMAIL if you have any questions.

|