The Amperor Tunable White LED Fixture solution

to Achieve True Color Uniformity among Fixtures

Amperor is thrilled to announce a groundbreaking achievement - the successful development of the industry's first True Closed-Loop Tunable White LED Fixture solution. This innovative solution incorporates an XYZ sensor, allowing for real-time monitoring and dynamic adjustment of the fixture's color output. With this advancement, we can now ensure unparalleled color uniformity in even the most extensive installations of tunable white fixtures. Say goodbye to the frustration of mismatched fixtures on the job site, as Amperor's solution guarantees a consistent and visually pleasing lighting experience, resulting in greater customer satisfaction and increased business opportunities for you.

In our relentless pursuit of addressing color uniformity issues that have plagued the lighting industry in previous generations of tunable white fixtures, Amperor has gone above and beyond. We have enriched our solution with additional features to enhance its versatility and functionality. These include Dim-to-Off and Dim-to-Warm capabilities, a Virtual Gamut setting for expanded color options, and a convenient one-button calibration process. With these added features, Amperor's solution not only solves the color uniformity problem but also provides a comprehensive and user-friendly lighting solution that meets the diverse needs of our customers.

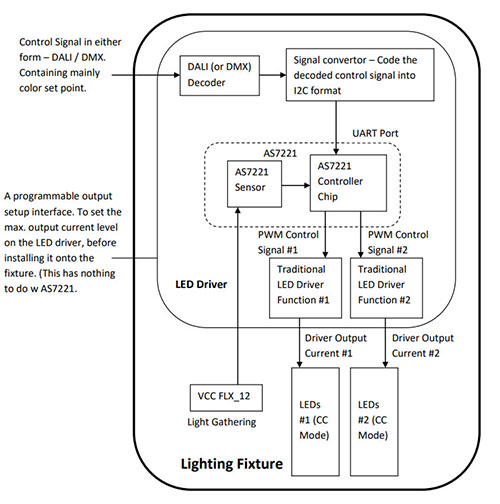

Design Concept

Our cutting-edge solution seamlessly processes control signal inputs, decoding them and transmitting the corresponding commands to the primary controller IC. Leveraging sensor feedback that provides real-time data on the current Correlated Color Temperature (CCT) stage of the fixture, the controller IC dynamically adjusts the percentage of output in the two channels: warm white and cool white. This precision control ensures that the desired CCT stage is achieved with utmost accuracy and efficiency.

Our solution is compatible with two widely accepted input control signals: DALI and 0-10V control. For the latter, there are two 0-10V control ports available – one designated for dimming control and the other for CCT adjustment. Looking ahead, Amperor has strategic plans to expand the solution's capabilities to include compatibility with DMX control, offering even greater flexibility for users.

With a total power output of 50W shared across the two channels, this solution allows for the allocation of the 50W limit to a single channel if needed. As part of our commitment to meeting diverse requirements, Amperor is also preparing to introduce both 25W and 100W solutions, catering to a wide range of applications and lighting scenarios.

Please see the Tunable White Solution Design Block Diagram Below:

Calibration

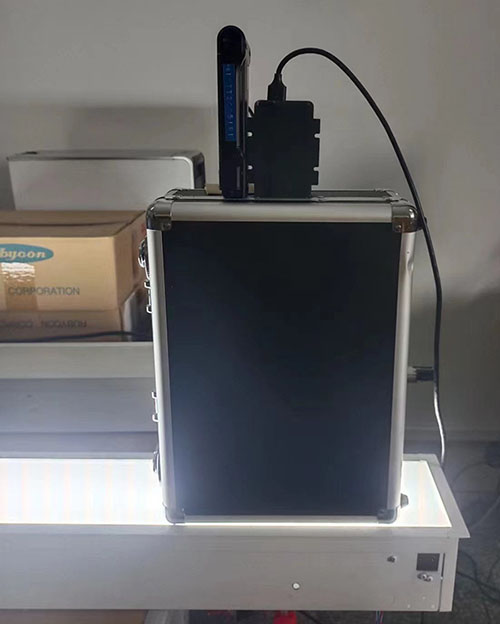

When it comes to integrating sensors into our solution, ensuring their precise calibration is of paramount importance. To streamline this crucial calibration process, Amperor has developed a dedicated calibration box designed for use in the fixture production line. This calibration box boasts several key features:

- Portability and Convenience: The calibration box has a total weight of just 1kg, making it easily portable and maneuverable within the production environment.

- Bottom Opening Design: The opening of the box, used to gather fixture light output, is conveniently located on the bottom. This design allows operators to leave the production fixture in its default orientation, facing upward. The calibration box can then be effortlessly placed above the fixture during operation.

- Protection for Fixture Surface: The box's opening is equipped with soft materials to minimize the risk of scratching the fixture surface during calibration procedures.

- Optimal Calibration Environment: Inside the box, we've applied the darkest available paint on the market, creating an environment that simulates a dark room. This ideal setting ensures accurate and consistent calibration results.

- Efficient Calibration Software: Our calibration software includes both calibration and self-evaluation functions, all completed within a remarkably short time frame. In fact, no more than 2 minutes are needed to complete a full calibration cycle.

By utilizing our purpose-built calibration device and software, fixtures undergo a proper calibration process that ultimately results in achieving output color uniformity, meeting the highest standards of precision and quality.

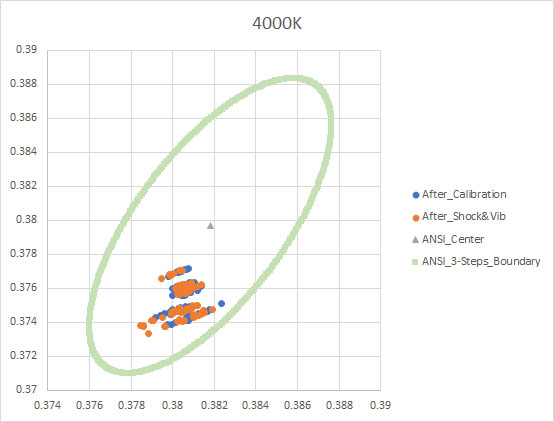

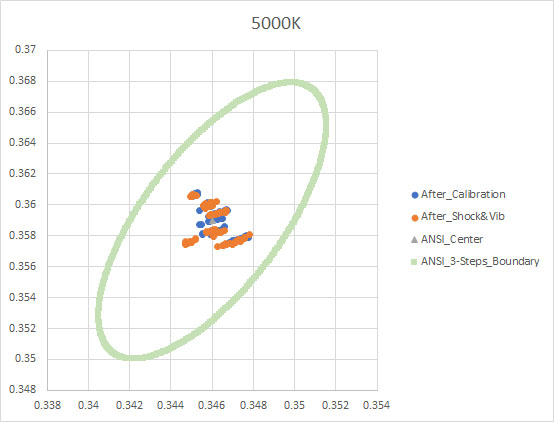

Color Uniformity Case study

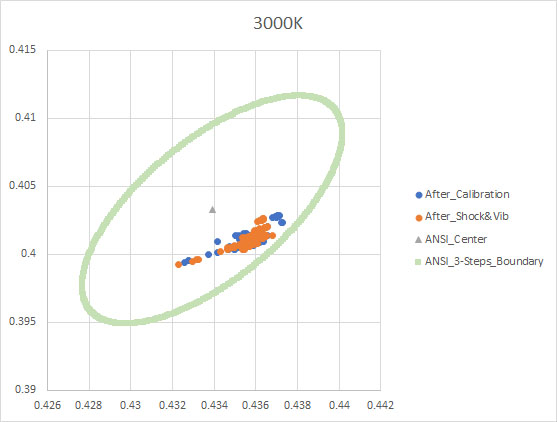

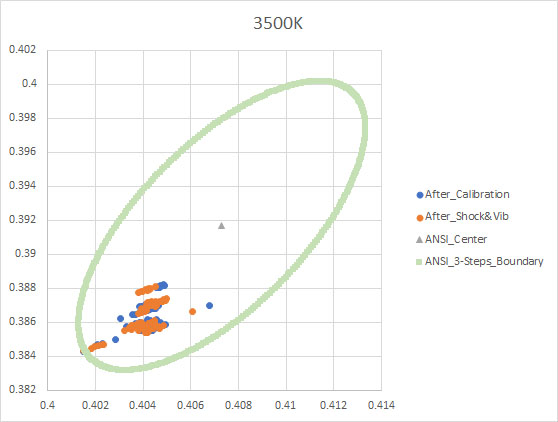

Our solution design goal is to consistently achieve output colors within a tight 3-step MacAdam Ellipse (SDCM) boundary, utilizing the ANSI center as our reference point. This meticulous approach ensures that our fixtures can display impeccable color uniformity on the job site.

To illustrate our commitment to this design goal, we present an example featuring the output data from 10 different fixtures, all of the same model and equipped with Amperor's tunable white solution. The results are displayed on a Chromaticity Diagram, and they encompass various Correlated Color Temperature (CCT) settings, including 3000K, 3500K, 4000K, and 5000K.

The blue dots on the diagram represent data collected after calibration, showcasing the remarkable precision achieved by our solution. Furthermore, the red dots depict data gathered following an industry-standard vibration test, validating that our fixtures maintain color uniformity even after the rigors of shipping.

As you can clearly observe, regardless of the chosen CCT setting, all the data points fall within the 3 SDCM boundary. This unequivocally demonstrates that our solution consistently delivers on its promise of achieving exceptional color uniformity, meeting the highest industry standards, and ensuring a visually pleasing and consistent lighting experience.

3000K Output on Chromaticity Diagram:

3500K Output on Chromaticity Diagram:

4000K Output on Chromaticity Diagram:

5000K Output on Chromaticity Diagram:

|